Manufacturing talent: Kansas production mainstay designs its niche, from warfighters to healthcare

August 15, 2023 | Matthew Gwin

Startland News’ Startup Road Trip series explores innovative and uncommon ideas finding success in rural America and Midwestern startup hubs outside the Kansas City metro.

TOPEKA — The leader of a Kansas company specializing in custom equipment design and manufacturing hailed the work of its nearly 500 employees for allowing the organization to thrive during a time when “everybody suffered.”

Polo Custom Products, founded in 1947, actually accelerated its growth during and after the COVID-19 pandemic, seeing revenue spike 28 percent in 2022, and another 29 percent in 2023 so far, according to CEO Kent Lammers.

“I’ve been really proud of our team for the scaling of production required to facilitate that growth,” Lammers said. “We primarily made up that difference here in Topeka. From August 2021 to 2022, we went from zero associates to more than 80. That success is a testament to all the hard work those folks do.”

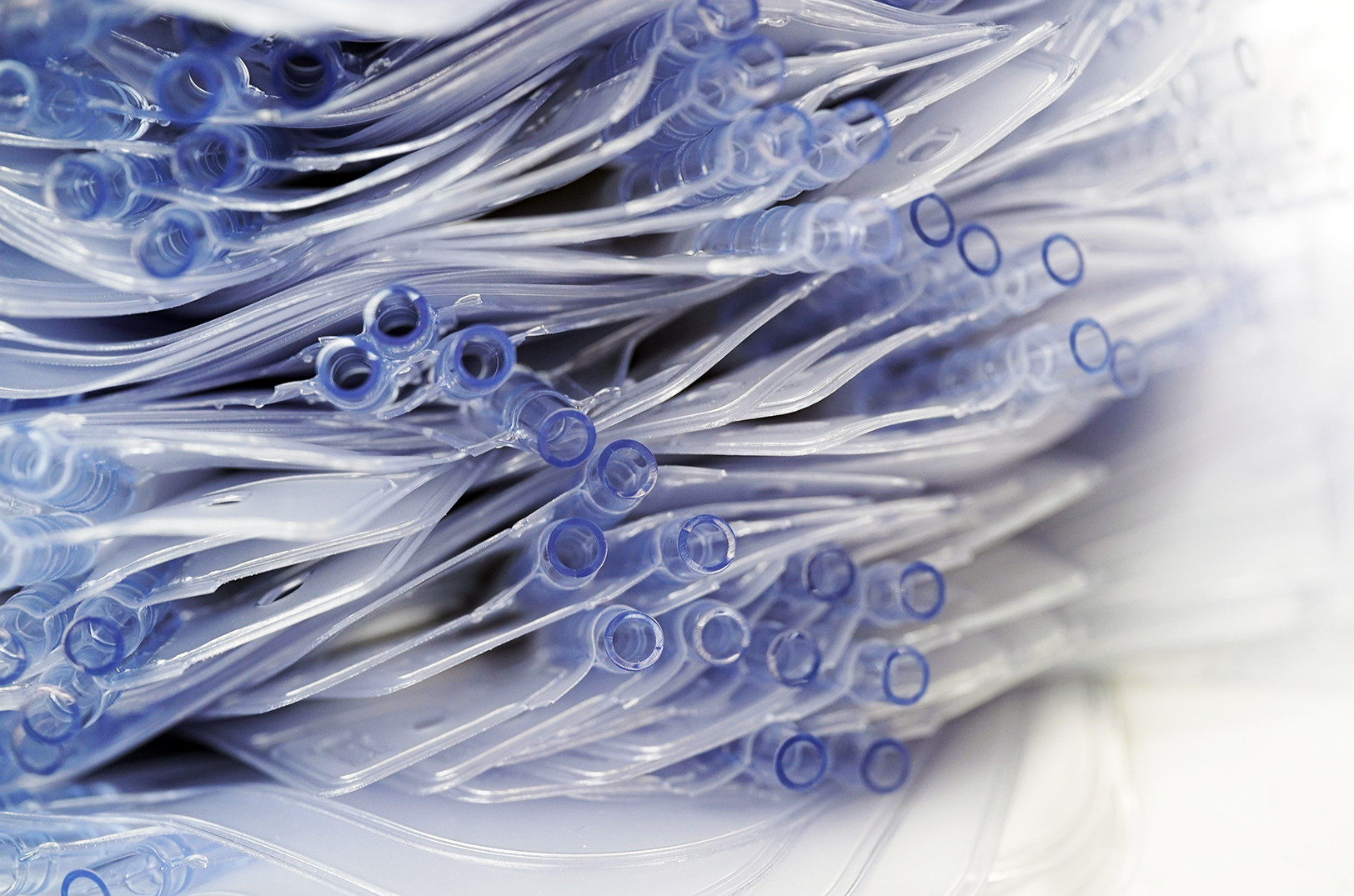

Topeka-based Polo Custom Products designs, engineers, and manufactures custom applications used in the medical, fire and safety, aerospace, industrial, and military industries.

Items like hospital collection bags, aviation oxygen masks, and helmet liners are sewn and heat sealed in the company’s three manufacturing facilities, including the recently-opened Topeka location, one in Iowa, and another in Mississippi.

Polo Custom Products also operates its corporate headquarters in Topeka, having called Kansas’ capital city home since the 1970s, according to Lammers.

The organization’s roots are firmly planted in Topeka, Lammers said, noting that the region’s talent pool and pro-business climate have helped to fuel Polo Custom Products’ growth.

“We’ve seen a renewed interest in talent development in our region of Topeka and Kansas City,” Lammers said. “Talent is very, very important. We feel like with Washburn University, Washburn Tech, and some of the initiatives taking place through the Greater Topeka Partnership, that’s created a positive environment and climate for business.”

Deployed globally

Beyond its expansion of facilities locally, Polo Custom Products continues to grow into “a global company,” Lammers said.

The company manufactures 75 percent of its products in its United States facilities, partnering with organizations in Vietnam, China, and the Dominican Republic for the remainder, he said.

Because of its decades-long relationship with the Department of Defense (DoD), Polo Custom Products sees many of its manufactured items make their way across the globe, too.

Prior to the Desert Storm operation in the early 1990s, the DoD worked exclusively with Polo to design a protective chemical patient wrap, which Lammers described as similar to a sleeping bag that can protect the spread of chemical contamination among warfighters.

“It was custom in nature, but it was kind of our invention,” Lammers said of the patient wrap. “We have a lot of credibility because of that. … We have a very good reputation with the federal government.”

Polo hasn’t produced any patient wraps in several years, Lammers shared, adding that the company typically has to wait for the government to reach out, then be prepared to respond quickly.

“A lot of it is timing with regard to the federal budget, the thoughts on military spending, and all those variables that are outside of our control,” Lammers said.

“It kind of happens all at once,” he continued. “We’ll get a contract, and there will be a lot of whatever it is that we need to make, and then we may not see another one for a year, or two, or three.”

Polo Custom Products also works as a subcontractor for other businesses that serve the government, Lammers noted.

‘Start-to-finish’ customization

As was the case with the chemical protective patient wrap, Polo Custom Products earns its reputation with its customers because the company focuses on working with clients to create customized solutions, according to Lammers.

“It’s a very two-way, communication-driven situation,” Lammers said. “We like to react to what our customers say. If they don’t like a design, we’re OK with that. We’ll help design something different, or we’ll lean more upon the customers’ designs.”

Polo is a “start-to-finish” design and manufacturing company, Lammers said, meaning that the organization employs product designers, engineers, and manufacturers who can complete each step of the process that turns product ideas into realities.

“We have a very talented and experienced team that can create something from drawing to prototype to sample to finished product,” he said.

Polo Custom Products are not in any retail environment, Lammers noted, so building and maintaining relationships with existing customers is critical.

Polo recently worked with a client in the medical industry to help launch one of the fastest-to-market products in that company’s history, according to Lammers, who added that the product was able to be scaled rapidly without any backorder.

“We’ve found that our legacy customers, and our new customers, really like our engineers being able to talk to their engineers to figure out a solution that’s meeting their needs more appropriately,” he said. “We feel that gives us an innovative approach.”

Human-centered growth

Lammers sees Polo Custom Products as “poised for growth,” he said, noting that the company hopes to continue hiring at its Topeka production facility until it reaches 150-200 employees.

“The people who are driving that [growth] are also very entrepreneurial, and very motivated by being part of a company that’s growing,” he said. “Their goals and aspirations are in alignment with ours. We’re very excited about that growth, and we wouldn’t be experiencing it without their talent.”

To keep that trajectory moving upward, Polo’s leadership team emphasizes building a human-centered company culture, Lammers said.

“The company culture, I think, is the most important factor driving talent coming to work here,” he said. “We’ve always had pride in the fact that we were a flexible company, and that flexibility just became a little bit more pronounced after the pandemic.”

Employees who can work remotely are allowed to do so in a hybrid environment, he said, while those who cannot are offered flex scheduling options, such as four-day work weeks.

Supervisors are discouraged from micromanaging and encouraged to find reasons to praise employees for a job well done, instead of only communicating when mistakes occur.

Lammers meets with every new hire — either in-person or virtually — and makes it his personal policy to respond to every email from an employee within 24 hours, he added.

The organization also provides a mentor to all new employees to help get them acquainted with their role and make them feel comfortable, Lammers said.

“It’s a pretty simple concept, but a lot of companies fail to do it,” he said. “When somebody’s brand new, they’re probably nervous, so when someone can say, ‘Let me help you succeed,’ that’s where a company can really stand out.

Overall, Lammers feels that Polo Custom Product has built its success by protecting its people, an asset even more valuable than its products.

“I think we are able to stay agile by keeping a culture that focuses on people who have lives to live outside the company,” Lammers said. “I think any company is shortsighted if it’s not trying to manage an environment that considers both.”

This series is possible thanks to Go Topeka.

Go Topeka seeks economic success for all companies and citizens across Shawnee County through implementation of an aggressive economic development strategy that capitalizes on the unique strengths of the community.

Featured Business

2023 Startups to Watch

stats here

Related Posts on Startland News

Report: Kansas City startups snagging more dough in 2016

Kansas City has made significant strides when it comes to improving access to early-stage capital, though its relative volume still lags other startup hubs, according to a recent report. In the first three months of 2016, Kansas City has boosted its total capital raised by about 297 percent when compared to the same time period…

Fund me, KC: MyCroft AI to take on Amazon Echo, Siri

Startland News is continuing its segment to highlight area entrepreneurs’ efforts to accelerate their businesses. This is an opportunity for entrepreneurs — like MyCroft AI CEO Joshua Montgomery — to share their stories to gain a little help from their supporters. If you or your startup is running a crowdfunding campaign, let us know by…

The Lean Lab partners with 4.0 Schools to innovate KC education

More than 100 years ago, our education system was designed and built to prepare an early-1900s workforce for the industrial age. Today, children are learning with iPads and Youtube, but the bones of the traditional liberal arts structure remain similar to what our great-grandparents experienced. Local education innovation incubator The Lean Lab hopes to change…