New in KC: How two OU alumni secured over $1M from NASA, US Air Force for 3D printing startup

September 2, 2021 | Channa Steinmetz

Editor’s note: New in KC is an ongoing profile series that highlights newly relocated members of the Kansas City startup community, their reasons for a change of scenery, and what they’ve found so far in KC. This series is sponsored by C2FO, a Leawood-based, global financial services company. Click here to read more New in KC profiles.

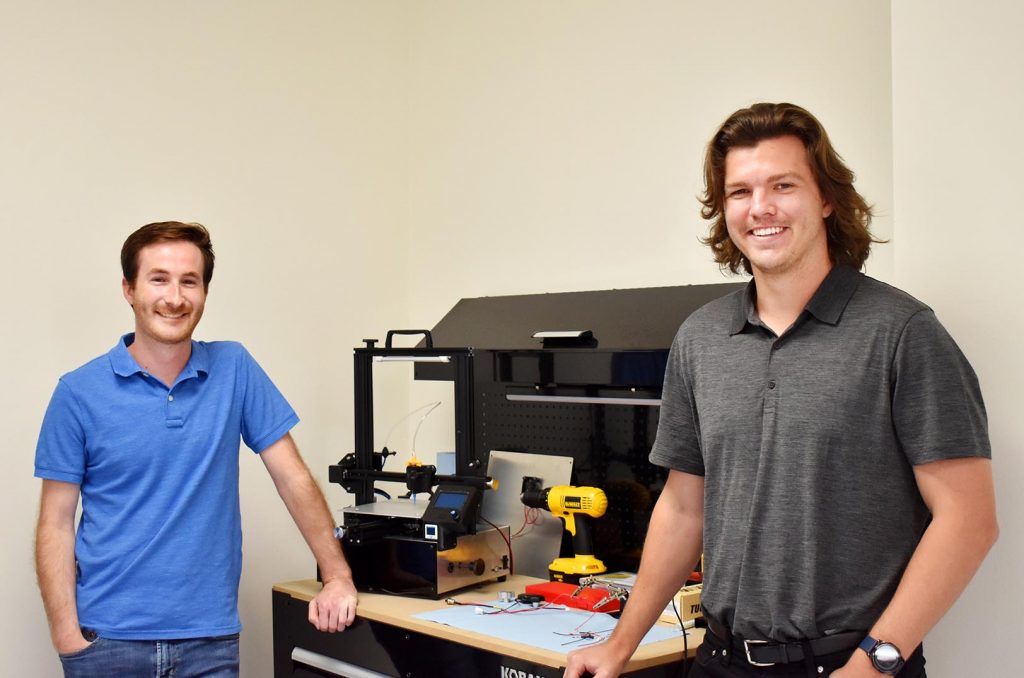

Replicating the founding catalyst for many pandemic-era startups, COVID-19 gave recent transplants Blake Herren and Ryan Cowdrey the headspace they needed to launch Raven 3D Printing — a state-of-the-art 3D printing startup now headquartered in KCK.

“COVID gave us the bit of free time that we needed,” said Herren, who graduated from the University of Oklahoma (OU) in 2021 with a Ph.D. in mechanical engineering. “It forced me out of the lab at OU, and Ryan had been working full-time. We likely would not have been able to focus as much on Raven 3D without COVID.”

Raven 3D Printing was founded in June 2020 with the mission of establishing a new era of manufacturing through 3D printing the highest quality polymers and composites, they explained.

“We are focused on printing thermoset materials, so they’re much higher performance [and] higher strength, lower weights typically, and much higher durability and resistance to chemicals and lights,” Herren noted.

Cowdrey and Herren met while students at OU, each exploring the possibilities of 3D printing. Cowdrey utilized 3D printing to prototype automotive parts while participating in Formula Society of Automotive Engineers; and Herren did research on 3D printing while in graduate school.

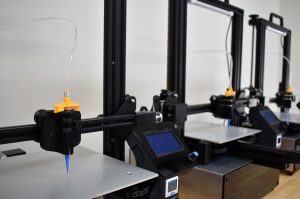

“It started off just building printers, then testing printers, and now we’re prototyping our own,” Herren said. “So it’s been an exciting journey in the 3D printing space so far.”

What is Direct Ink Writing?

Direct Ink Writing (DWI) is a method of 3D printing that utilizes ink, gel or paste to build a structure. It is typically achieved by extruding material out of a syringe or screw extruder — allowing for practically any liquid material to be printed. Materials used in DIW include thermoset polymers, nanocomposites, biomaterials, ceramics, food products and more, according to Raven 3D Printing.

The duo created a desktop Direct Ink Writing (DIW) printer that extracts materials using air pressure — rather than a mechanical plunger — resulting in cleaner and more precise products.

As the two aim to outperform their competitors, they are currently working on “in-situ” curing methods. In-situ curing is the process of liquid material solidifying immediately as it is deposited, which typically requires heat and can be limiting to the size and complexity of a part, they continued.

“Raven 3D is currently focused on the [research and development] of in-situ curing methods and materials to locally heat and cure material immediately upon extrusion,” they noted on Raven 3D Printing’s website. “In-situ curing DIW harnesses the unique capabilities of composite and nanocomposite materials and will enable a revolution in polymer-based 3D printing.”

Click here to check out Raven 3D Printing.

Attention from NASA, Air Force

The duo’s up-and-coming technology has even earned them Small Business Innovation Research (SBIR) and Small Business Technology Transfer (STTR) contracts from NASA and the U.S. Air Force.

“We wouldn’t have even seen the applications for these SBIR programs if it wasn’t for Tom Wavering, the executive director at the [OU] Innovation Hub,” Herren recalled. “… The first topic he brought to us and that we applied to was for the army. We didn’t win at the time.”

Herren and Cowdrey then took time to focus on learning how to write proposals for these contracts and won their second proposal for the U.S. Air Force in November.

“We were also awarded a phase one from NASA earlier this year,” Herren said, noting that they have over $1 million in government funding for research and development.

“We have a good start coming in next year to develop these technologies to print newer and better materials — and to do great things in the [Department of Defense] and across the aerospace community,” Herron said.

Engineers-turned-entrepreneurs

Graduating from OU in May 2020 with his Master’s degree in mechanical engineering, Cowdrey was quickly hired as an engineer and moved to Kansas City, Missouri — just miles away from his childhood hometown of Overland Park.

“Building a company in Kansas City was something I was really excited about,” Cowdrey shared. “Growing up, I really liked building things and creating, so it’s cool to be able to come back and continue to do that.”

“I have a lot of family that’s nearby as well, so it made sense to build a startup here — near family and in a bigger city that has more entrepreneurial opportunities,” Herren added, emphasizing their eagerness to get connected to business mentors.

“With both of us being engineers, we need to do a lot of learning on the business side,” he continued. “Starting a company is a whole different experience than doing research in a lab. … We’re hoping that we can connect with [experts and other tech startups] in Kansas City and learn from them.”

Along with advancing their technology, the duo hopes to double their team.

“If you’re interested in 3D printing or have experience in 3d printing, we’re looking for electrical engineers, mechanical engineers, maybe chemists down the line,” Herren said. “It’s just us right now, but with our phase two proposal, we’re excited to hire one or two engineers.”

Connect with Ryan Cowdrey and Blake Herron on LinkedIn.

2021 Startups to Watch

stats here

Related Posts on Startland News

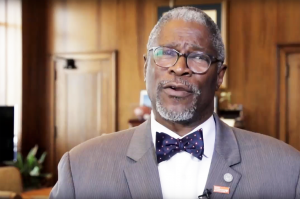

Vote now: KCMO competing for spot in accelerator focusing on gender, racial inclusion

KCMO already is a five-star city, Mayor Sly James says, but a new accelerator program could make it even better. “Kansas City’s startup community is growing and innovating, but women and people of color are being left behind,” James says in a pitch video for Living Cities City Accelerator program. A coalition of local organizations,…

Go print yourself! Overland Park doob shop turns selfie concept into 3D replicas

A new shop in Overland Park is supplanting the selfie with the mini me. After first opening shops in Los Angeles and New York City, the Germany-based 3D printing firm doob has arrived in the Kansas City area to 3D print people, groups and pets. The technology, process and results capture moments in time customers…

KCultivator Q&A: Reggie Gray finds magic in connecting entrepreneurs with Black Privilege, no excuses

Editor’s note: KCultivators is a lighthearted profile series to highlight people who are meaningfully enriching Kansas City’s entrepreneurial ecosystem. The KCultivator Series is sponsored by WeWork Corrigan Station, a modern twist on Kansas City office space. He’s left his “Magic Man” persona behind, but Reggie Gray can’t quite shake the performer inside him, he said. “Whenever I…

KCSF pivoting away from Village Square coworking, eyes bigger community impact

Village Square developed a waiting list soon after opening in 2015, said Adam Arredondo. But as larger coworking spaces with more amenities and resources debuted, interest waned in the 3,000-square-foot operation at 45th Street and State Line Road. “What’s our most valuable contribution to the community right now?” said Arredondo, CEO of the nonprofit Kansas…